- About Us

- SealCoating

- Our Process

- Materials

- Gallery

- FAQ's

- Why Sealcoat?

- When to Sealcoat

- Things To Ask A Contractor

- Best Temperature for Sealcoating

- Parking Lot Maintenance 101

- Sealcoating Myths Debunked

- Asphalt Maintenance Glossary

- Cost Savings of Sealcoating

- Sealcoating Benefits

- Double Life of Your Asphalt With Sealcoating

- Benefits of Sealcoating Your Parking Lot

- Crack Filling

- Products

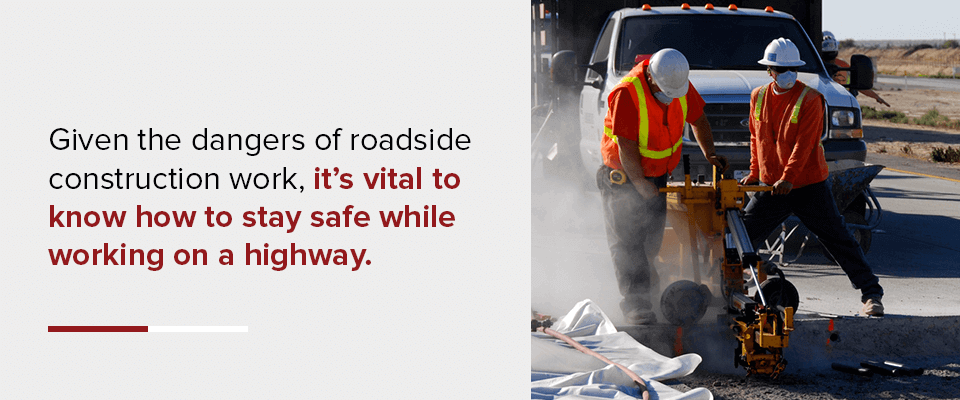

Tips for Road Construction Workers to Minimize Hazards

For every 4 billion vehicle-miles of travel in the United States, there is a work zone fatality. These incidents account for 10% of roadway congestion and 24% of roadway delays — and hundreds of worker and pedestrian fatalities each year. The Bureau of Labor Statistics (BLS) cites transportation incidents as the most frequent type of work-related fatalities. In fact, they caused 40% of all reported work fatalities in 2018. That's the highest number of fatal work incidents in the U.S., making the construction industry — especially those working alongside highways — one of the most dangerous fields in the U.S.

Call Us for Traffic Safety EquipmentThe construction industry recognizes the "fatal four" accident types, which result in the majority of all work-related injuries and fatalities. These common hazards include:

- Falling

- Being struck by an object

- Electrocutions

- Getting caught in or between equipment

How do we keep construction workers safe along highways? By minimizing construction hazards and taking steps to promote road construction safety. Everyone has a role to play in construction work zone safety, including pedestrians, crew members and site managers. Each person must practice safety-first habits and remain vigilant of their surroundings.

Table of Contents

- Common Causes of Highway Construction Injuries

- Safety Standards for Highway and Construction Sites

- Safety Tips for People Who Work on Highways

- Administrative Controls

- Engineering Controls

- Wear Appropriate Personal Protective Equipment (PPE)

- Daniel B. Krieg’s Focus on Highway Contracting Safety

Common Causes of Highway Construction Injuries

According to the National Work Zone Safety Information Clearinghouse, there has been a steady rise in fatal crashes and work zone fatalities in the U.S. since 2009. In 2018, there were 755 total fatalities, with 672 of those involving crashes. Of those fatalities, 124 were construction workers.

Between 2011 and 2016, the following events led to fatal highway construction injuries:

- Pedestrian vehicular incidents accounted for 50.2%

- Motorized vehicles accounted for 13.2%

- Being struck by an object or piece of equipment accounted for 10%

- Falling to a lower level accounted for 7.9%

- Electrocution accounted for 3.9%

- Being caught in or compressed by objects or equipment accounted for 1.9%

- Other unlisted factors accounted for 13%

As you can see, pedestrian vehicular incidents were the leading cause of highway construction injuries, causing more than half of those reported in the five-year period. Of those pedestrian vehicular incidents:

- 61.4% of fatal injuries were caused by a forward-moving vehicle striking the victim in a work zone

- 24.7% of fatal injuries were caused by a vehicle backing up in a work zone

- 9.4% resulted from a vehicle propelling another vehicle in a work zone, causing it to strike the victim

- 4.5% were related to other, non-listed pedestrian vehicular incidents

The U.S. Department of Transportation Federal Highway Association (FWHA) lists large trucks and buses as the leading vehicles involved in worker fatalities, though pickup trucks, semis and tractor-trailers, SUVs, vans and equipment vehicles also pose a threat. Speeding was a factor in a significant number of work zone crashes. The majority of these incidents occur on arterial roads, followed by interstates.

One of the most significant non-vehicular causes of on-road and off-road worker injury is crystalline silica dust. Silica dust forms from crushed rock, sand and concrete, and frequent inhalation may cause lung disease, lung cancer, chronic obstructive pulmonary disease (COPD) or kidney disease. These illnesses can result in disability, sickness or death. OSHA reports that nearly 2.3 million workers are exposed to silica on the job site. They have compiled a database with specific instructions for preventing silica dust and protecting workers, depending on the source of the dust and what machinery is producing it.

Daniel B. Krieg is committed to worker safety, which includes ensuring you have the highest quality products to keep employees safe and healthy.

Safety Standards for Highway & Construction Sites

The Occupational Safety and Health Administration (OSHA) developed standards to improve workplace safety and health. In 2016, they renewed their alliance to keep roadway construction workers safe from run-over and back-over hazards, damaging noise, sprains, strains and silica-related illness. Part 1926 addresses safety concerns for construction sites, specifically the use of danger signs, caution signs, exit signs, directional signs and traffic signs. The following requirements are only a few examples:

- 1926.200(g)(1): Construction sites shall be posted with legible traffic signs at points of hazard.

- 1926.200(g)(2): All traffic control signs or devices used for the protection of construction workers must conform to established standards from the Manual on Uniform Traffic Control Devices (MUTCD).

- 1926.200(h)(1): Accident prevention tags should be used as a temporary way to warn employees about an existing hazard, such as defective tools or equipment.

- 1926.200(a): The use of flaggers for signaling must adhere to Manual on Uniform Traffic Control Devices standards.

Part VI of the Manual on Uniform Traffic Control Devices, issued by the FHWA, provides additional guidance on standards for traffic signs, road surface markings and signals. Section 6D.03 requires the use of high-visibility safety apparel working on federal highways, citing the high degree of vulnerability that workers and responders face near roadways and acknowledging the need for efficient completion of road projects. They also support the usage of temporary traffic barriers, worker safety planning, adequate training for all workers and enforced speed reduction.

The National Institute for Occupational Safety and Health (NIOSH) Construction Equipment Visibility webpage provides guidance on preventing back-over injuries and fatalities while advising on proper equipment operation and servicing. This includes identifying blind areas around work zones for increased visibility. NIOSH has led the effort in reducing the number of workers struck by road construction equipment.

The American National Standards Institute (ANSI) provides standards for high visibility safety apparel and headwear, specifically through ANSI 107-2010. ANSI A10.47-2020 provides guidance on flagger safety, run-over and back-over prevention, equipment operator safety and personal protective equipment. In 2020, ANSI updated standards to include disposable high-visibility coveralls, adjustments to bursting strength standards for knitted materials and an emphasis placed on overall luminance in garments for additional visibility at the work site.

The National Highway Work Zone Safety Program (NHWZSP) also works to enhance the safety of highway work zones for motorists and highway workers alike. The NHWZSP provides standardization of traffic control devices and traffic control plans in addition to work site evaluation. The NHWZSP also introduces innovative technologies to improve safety.

National Work Zone Awareness week, which usually takes place in April each year, is a joint effort by the American Traffic Safety Services Association (ATSSA), the American Association of State Highway and Transportation Officials (AASHTO) and the FHWA. It's a multi-day outreach event that focuses on raising public awareness surrounding work zone risks and safety precautions.

It’s important that work site safety plans consider the above standards and guidelines. All safety plans should include hazard assessments to identify risks and outline provides to mitigate them.

Safety Tips for People Who Work on Highways

Given the dangers of roadside construction work, it’s vital to know how to stay safe while working on a highway. Consider the following safety tips to protect yourself from work zone injuries:

- Wear high-visibility clothing: High-visibility clothing — including fluorescent or reflective arm bands, hats and vests — are essential when working in dark or low-light conditions. This includes working during inclement weather or in heavily shaded areas.

- Be observant: Be sure to look before you shift your position. Pay attention to all potential hazards, particularly blind spots, for moving construction equipment. If possible, have spotters on-hand to keep an eye on roadway traffic while others work. If you are a spotter, know where to stand for an unobstructed view and confirm hand gesture meanings. Understand channel lanes where walking is prohibited and where vehicles enter and exit the work site. Remain aware of any traffic in and out of the work site. Flaggers should be particularly vigilant when it comes to understanding traffic flow and work zone setup, and ensure that traffic channeling devices are properly placed.

- Understand communication signals: Understand all communication signals used between equipment operators and workers on foot. Stay up-to-date on signal training and do not allow workers who have not undergone communication training in the work zone.

- Don’t stand under suspended equipment: Never stand under suspended equipment like buckets, booms or arms. Be especially vigilant in areas that use buckets.

- Apply parking brakes: Be sure to apply all parking brakes on equipment. Vehicles parked on inclines should use appropriately sized blocks placed behind or in front of the tires.

- Use a seat belt: Don’t operate any vehicles, like rollers, without wearing a seat belt.

- Be cautious when approaching vehicles: Be careful about approaching machinery without first signaling the vehicle operator to shut down the equipment and getting acknowledgement from the driver.

- Make eye contact before moving or operating equipment: Equipment operators shouldn’t move equipment without making eye contact with workers in the vicinity.

- Don’t ride on moving equipment: Never ride on moving equipment or use equipment for anything other than its intended use.

Flaggers should keep enough distance from other highway workers to ensure they can be distinguished by passing motorists. They should also use good sight communication or two-way radios to communicate with fellow flaggers. This will minimize risk on highway work sites.

All workers should be careful not to assume they can be seen by equipment operators or motorists. You’ll need to make sure that motorists slow down and equipment operators acknowledge your presence.

Administrative Controls

If you’re supervising or managing a highway construction project, consider the following tips on how to keep highway workers safe with administrative controls:

- Complete a risk assessment: A risk assessment, based on OSHA regulations and standards outlined in the Manual on Uniform Traffic Control Devices, will help identify the risks workers face. The plan should outline what measures are needed to eliminate or mitigate those risks.

- Train workers on a safe work zone: Be sure to train workers on how to set up and maintain a safe work zone. Anyone flagging traffic should know to follow the safest practices. When it comes to traffic control, it’s important to warn motorists of traffic zones far in advance with stationary and light-up signs, cones, flaggers and other methods of warning.

- Require equipment training: Be sure that employees know how to maneuver around equipment and take all precautions for their own safety and that of others. If your workplace does not have extensive equipment training, consider contacting the equipment manufacturer for a recommendation.

- Encourage responsibility:Encourage employees to take some time to walk around the site and check for hazards. Responsibility in the work zone also includes staying in your assigned area, completing each given task and remaining vigilant of your surroundings.

Once you've done everything in your power to enforce safety in road construction work zones, you must continue to monitor and adapt the work site until the project is finished. Weather, traffic flow patterns, crew changes and equipment failure are commonplace at highway jobs, and they can cause a chain reaction of events that endanger workers. Hold all crew members accountable for their roles and maintain order to minimize the risk of dangerous miscommunication.

Engineering Controls

You can also use engineering controls to protect your workers, such as:

- Separate workers from traffic: Separate workers from traffic as much as possible while still assigning flaggers to manage traffic in the road. Flaggers should know never to turn their backs to oncoming traffic.

- Establish safe traffic flow: To ensure that workers and vehicles move around the work site safely, it’s vital to establish where workers can enter and leave the site. There should also be procedures for when construction equipment is backing up and where it could come into contact with workers.

- Consider which vehicles to use: Traffic speed and the size of the work site are key factors in determining which equipment to use.

- Improve visibility: It’s important to ensure as much visibility as possible for workers. If visibility is low, use spotters to look out for potential hazards. The use of reflective uniforms also helps improve visibility. Additional work lighting may be necessary, in addition to reflective tape on equipment. Whenever possible, schedule the most dangerous work — like tasks near busy roads or high drop-offs — early in the day and during periods of predicted low traffic.

- Use proper safety barriers: While light traffic might call for orange safety cones, heavy traffic may require barrels or even temporary concrete barriers.

- Mark utility lines: Identifying utility lines will help prevent electrocutions.

- Ensure employees are vigilant around moving equipment: Employees must never stand in front of or behind an operating vehicle since equipment can often block an operator’s field of vision.

- Manage noise level: Be sure to monitor the noise level to prevent hearing loss or injury. You should advise workers to wear earmuffs or earplugs to protect them from high-decibel noise.

- Consider new technology to improve safety: Glass-beaded paint reflects oncoming headlights at night and makes it easier for motorists to exercise added caution. Electric signs with alternative warnings can alert workers when someone drives through a barricade. Rumble strips are a useful way to communicate caution and remind drivers that they’re entering a work zone.

- Ensure employees wear personal protective gear: Construction workers should always wear appropriate protective gear such as hard hats, reflective clothing and steel-toed shoes.

With improved visibility, safe maintenance of traffic as well as sufficient planning and communication, many potential hazards can be avoided.

Wear Appropriate Personal Protective Equipment (PPE)

OSHA regulates employers to provide construction employees with proper personal protective equipment (PPE) to supplement administrative and engineering safety controls. OSHA standards provide criteria for personal protective equipment, including protection for the head, feet, eyes, face, hearing and respiration. In many cases, proper safety equipment could be the last defense between a worker and a possible injury. However, many injuries occur because employees choose not to wear the safety gear they have. This means that employers not only need to provide the PPE but must require employees to use it.

A risk assessment will determine what personal protective measures work best at a given construction site. Such an assessment will require some, if not all, of the following:

- Head protection: Hard hats protect against impacts from fixed and falling objects. Some hard hats may come equipped with face shields or ear muffs. Helmets should fit properly and never be altered. They should also be replaced after any heavy blow. Be sure to inspect them periodically for cracks or deterioration.

- Eye and face protection: Hard hats don’t protect the face, making safety goggles or face shields very important. When it comes to cutting, grinding, welding or nailing, eye protection is essential. Workers should also wear eye protection when working with concrete or harmful chemicals or when exposed to electrical hazards. Goggles might be tinted, and some offer side shields.

- Foot protection: Steel-toed boots will prevent toes from being crushed due to falling objects. Construction workers should also wear slip-resistant, puncture-resistant soles.

- Respiratory protection: When employees work with paint or are exposed to toxic airborne substances like silica, respiratory protection is vital. Respiratory protection can protect against pesticides, paint spray, fumes and even dust. Respirators must be cleaned to remain effective.

- Hearing protection: Be sure to use earplugs or earmuffs in work areas with high noise levels.

- Hand protection: Workers will need heavy-duty rubber gloves for concrete work and welding gloves for welding. Electrical hazards require insulated gloves and sleeves. Be sure to keep gloves snug and free of tears, holes and frays.

- High-visibility clothing: When visibility may be impaired, reflective clothing will be necessary or even required, depending on the project, work site and local regulations.

There are also additional considerations for anyone managing a construction team, to ensure protective gear doesn’t create dangers:

- It’s not enough to wear personal protective gear. Such gear should also be worn correctly to protect workers against dangers. Training may be necessary.

- Supervisors should remind employees to check clothing to ensure loose pieces or hair doesn’t get caught in machinery. Fall harnesses should be worn snugly, so there are no dangling straps.

- Supervisors should make sure employees face equipment when dismounting, in case clothing is caught in the machinery.

You should also wear hats and use sunscreen to protect yourself from the sun. Hydration is just one of many challenges facing construction workers, and many struggle with symptoms of dehydration. Drinking a cup of water before your shift, after your shift and every 20 minutes throughout the day will help prevent dehydration. Symptoms of dehydration include an excessively dry mouth, extreme thirst, dark-colored urine, dizziness and sudden or inexplicable fatigue. The better hydrated you are, the more productive you can be.

Worker fatigue is another personal hazard to watch out for. One study shows nearly half of surveyed participants report feelings of exhaustion on some work days in the average month, with 10% of those workers reporting fatigue on most or every day. According to the same report, fatigue has a serious influence on construction workers' physical and cognitive function. Exhausted workers are often less vigilant and productive and more susceptible to workplace injuries.

Daniel B. Krieg’s Focus on Highway Contracting Safety

Since 1933, Daniel B. Krieg has been offering quality products for homeowners, large and small contractors and government entities. We offer a wide variety of traffic safety products, personal protection equipment, signs, posts, geotextiles, drainage pipes, and many other highway contracting products. As a growing company, we remain committed to innovation by offering the most state-of-the-art equipment available.

Consider Daniel B. Krieg for highway construction safety equipment. We sell personal protection equipment such as safety vests, gloves, hard hats, protective clothing and safety glasses in our Harrisburg and York store locations. You can also find traffic safety items, including barricades, cones, parking blocks, fencing, signs and sign stands, safety flags, speed bumps and stop/slow paddles.

We understand your safety concerns and work to ensure you have the highest quality products to keep employees safe and healthy. Learn more tips for road construction safety and browse our online store today!

Contact Daniel B. Krieg For A Quote

Please contact Daniel B. Krieg, Inc. by filling out the form below, or by calling us at one of our locations.

Harrisburg Office

-

6730 Allentown Blvd.

6730 Allentown Blvd.

Harrisburg, PA 17112 Map It >> -

Mon - Fri: 7:00 am - 4:00 pm

Sat : Closed

Sun : Closed

Mon - Fri: 7:00 am - 4:00 pm

Sat : Closed

Sun : Closed -

800.334.4929

800.334.4929

717.564.2400

Fax: 717-558-2036 -

Contact Us

Contact Us

-

Leave a Review

Leave a Review

York Office

-

3331 Gulton Road

3331 Gulton Road

York, PA 17404 Map It >> -

Mon - Fri: 7:00 am - 3:30 pm

Sat : Closed

Sun: Closed

Mon - Fri: 7:00 am - 3:30 pm

Sat : Closed

Sun: Closed -

717.792.0284

717.792.0284

Fax: 717.792.0640 -

Contact Us

Contact Us

-

Leave a Review

Leave a Review

![]()

LEAVE US A REVIEW

Back To Top

Back To Top