Geotextiles in York, PA

For product specifications, please click the following images.

Our Geotextiles are available through our York office only. Call 717.792.0284 to order, delivery available. Click To View Product Ordering Information →

Call 717.792.0284 to OrderTable of Contents

1. What are Geotextiles?

2. How Geotextile Fabric Works

3. The Difference Between Woven and Non-Woven Geotextiles

4. Different Applications of Geotextiles

5. Benefits of GeoTac

6. Selecting Geotextile Fabric in Filtration Operations

7. Where To Buy Geotextile Fabric

8. Companies That Use Geotextiles

9. How To Improve Your Project Results with Geotextiles

10. Product Ordering Information

Geotextiles: What You Need to Know to Improve Project Results

Throughout history, engineers and construction companies have struggled with weak soils - and all the challenges that come with building on them. Erosion and loose foundational soil made for uncertain construction projects.

It wasn't until the 1950s when the application of woven permeable fabrics - now known as geotextiles - was shown to significantly improve soil strength and retention. But it took another 20 years before Dr. J.P. Giroud first used the term "geotextiles" in 1977 at a Paris engineering conference. That's when the idea of using geotextiles to improve paving and construction projects began to really catch on.

Today, woven and nonwoven geotextile fabrics have changed how civil engineering projects are executed. Modern geotextiles are made from more than 400 different materials, giving them a range of uses, from paving roads and filtering drainage to erosion control.

Geotextiles offer useful, simple and cost-effective solutions for improving the performance of almost any pavement or soil. Geotextiles are so important that there are annual engineering conferences centered on their specific design and use. A scientific journal, Geotextiles & Geomembranes, even published peer-reviewed novel research on this specific niche.

What Are Geotextiles?

Geotextiles are permeable fabrics. When used in soil, they generally serve five different functions:

- Separate: Placing a boundary between two things or areas

- Filter: Allowing a fluid to flow while removing or catching particulates

- Reinforce: Providing structural enhancement to an area

- Protect: Often in conjunction with separating, placing a boundary over soil or a foundation

- Drain: Removing fluid from an area or redirecting it to another area

Geotextiles are either woven - looking much like a mail bag - or nonwoven, in which case they could be needle punched or heat bonded. Nonwoven geotextiles may look like felt or iron felt. To put it simply, geotextile fabrics help make soil - and what rests on the soil - more structurally sound, strong and durable.

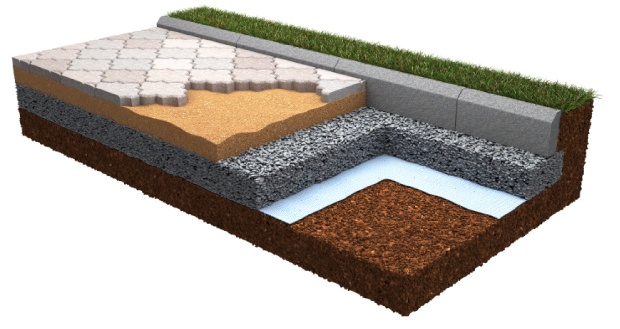

How Geotextile Fabric Works

Geotextiles provide strength and durability by separating a foundation or construction from the underlying soil. For example, if the pavement is laid on dirt, over time the lowest layer of the pavement will disassociate as the soil infiltrates the pavement. This leads to weaker pavement, reduced service life and greater maintenance costs.

Using a geotextile layer to separate the pavement from the ground helps maintain the structural integrity of the pavement over time. This is especially important in climates that undergo successive episodes of freezing and thawing. Geotextiles also help prevent the underlying soil from contamination, as well as the pavement from settling if the subgrade beneath the pavement sinks or shifts.

Some common applications of geotextiles and how the materials help:

![]() Reinforce weak or aging soil underneath roads, railways, airfields and embankments

Reinforce weak or aging soil underneath roads, railways, airfields and embankments

![]() Filtrate subsurface drains and rock seawalls

Filtrate subsurface drains and rock seawalls

![]() Drain and protect the lining systems for landfills and waste containment

Drain and protect the lining systems for landfills and waste containment

![]() Reduce beach erosion from wind and water in coastal applications

Reduce beach erosion from wind and water in coastal applications

![]() Protect the ground at stadium events from damage when temporary staging is used

Protect the ground at stadium events from damage when temporary staging is used

Let's examine the structural difference between woven and nonwoven geotextiles to better understand the specific application of each.

The Difference Between Woven and NonWoven Geotextiles

While woven and nonwoven geotextiles can be made from polypropylene - a thermoplastic polymer - they each go through a different manufacturing process, resulting in unique product characteristics.

Specifically, woven geotextile fabrics are manufactured by weaving narrow strips of film together to form one large piece. This results in a tough fabric with a higher load capacity. That's why woven geotextiles are used commonly for ground stabilization in roadway construction projects. However, the drainage characteristics of woven geotextiles are typically not as good as they are for nonwoven geotextiles.

Nonwoven geotextiles are felt-like fabrics manufactured by bonding with needle punching or, in some cases, heat. This characteristic allows the fabric to have excellent filtration and drainage characteristics. Since nonwoven geotextiles have higher permeability, they are the ideal choice for subsurface drainage applications such as pond underlayment, ditches, around pipes, erosion control or in any application dealing with high levels of runoff or site drainage.

Different Applications of Geotextiles

Before 1976, geotextiles had very few applications, but by the mid-1990s, over 500 million square meters of geotextiles were in place in North America. Geotextiles continue to be a growing area of market activity.

Filtration and Drainage

Geotextiles are most frequently used in filtration. Water or another fluid flows through the geotextile, and particles that are larger than the size of the weave are trapped by the geotextile. The concern in filtration applications is that the geotextile will eventually become clogged and will need to be replaced.

In drainage applications, geotextiles can facilitate the movement of liquids. Here, non-woven geotextiles are preferred. They're designed typically for short-term applications to wick or otherwise drain liquids from a particular area.

Erosion Control

Geotextiles also offer erosion control solutions - they're often used to firm up soil surfaces. The geotextile can help protect the surface from the eroding effects of wind and rain. It can also help reinforce soil, for example, along embankments that would otherwise face a greater likelihood of erosion and degradation.

Erosion control is becoming increasingly important in shoreline and close-to-shore installations. Geotextiles can help guard against wave erosion and have been used in Australia, Germany, the United Kingdom and the USA.

Moisture Barriers and Filter Fences

Geotextiles can also help provide a barrier to moisture when other chemicals are added to their composition. This application - often used in paving - reduces the amount of water that gets below the pavement and into the foundation or subgrade.

In addition, geotextiles can provide a filter fence - which, when reinforced, is known as a super silt fence - to protect streams, rivers, lakes or other bodies of water from runoff sediment that would otherwise contaminate the water source.

Our Geotextile Manufacturers

GeoTac

One geotextile often chosen for its filtering properties is GeoTac. GeoTac waterproofing membrane is a fabric that you can peel and stick where you want. Variations include polyester fibers, giving GeoTac extra durability. GeoTac is made of a polymer waterproofing adhesive bonded to a nonwoven polypropylene material.

GeoTac has an adhesive layer, which will bond to a surface and prevent or limit moisture. It can also provide a layer of protection to surfaces during construction operations.

GeoTac is used in parking lots when repairing cracks in the asphalt. It's also used in box culverts, which allow water to flow under roads, railroads or similar obstructions. Other applications include bridge decks, waterproofing and construction applications requiring moisture barriers before installing asphalt overlays and similar surfaces.

It meets the regulatory requirements of most state highway departments for strength and waterproofing pavements and bridges. GeoTac comes in different widths - from 12 inches to 48 inches - and is wound on rolls of 50 or 100 feet for easy deployment. You unroll it onto the desired surface and remove the GeoTac liner so that it can adhere to the surface. For even greater flexibility, GeoTac HS - the extra durable version of GeoTac - is resistant to the heat in asphalt pavement at temperatures up to 350 degrees Fahrenheit.

SKAPS GC140 Nonwoven Geotextile

GC140 is a type of needle-punched nonwoven geotextile produced by SKAPS Industries. It is a fabric made from 100% polypropylene fibers formed into a random network for added dimensional integrity. SKAPS GC140 is known for its versatility and durability, making it suitable for projects requiring soil separation, filtration and drainage.

GC140 is designed to provide strength, stability and filtration properties in various construction applications. SKAPS GC140 is commonly used in road construction, landscaping, erosion control and other civil engineering projects to improve soil stability, prevent erosion and manage water flow efficiently. Its nonwoven material effectively resists biological degradation, ultraviolet deterioration, rotting and naturally encountered acids.

Primary properties — including weight, grab tensile, tear strength and puncture resistance — comply with various ASTM standards. Rolls come in 360-foot lengths with 6 ¼, 10 ½, 12 ½ and 15-foot width options. SKAPS nonwoven geotextiles also meet National Transportation Product Evaluation Program (NTPEP) and Department of Transportation (DOT) regulations.

Differences Between GeoTac and SKAPS Nonwoven Geotextiles

Because of their unique structures and physical properties, GeoTac and SKAPS GC140 each offer advantages for specific applications. GeoTac's modified polymer waterproofing membrane offers exceptional strength and erosion control capabilities, making it ideal for stabilizing soil in heavy-duty applications in road construction and large-scale building projects. In contrast, professionals often choose GC140 first for its superior filtration capabilities, particularly for managing water flow and drainage in commercial landscaping projects.

While both geotextiles offer soil stabilization, GeoTac typically focuses on strength and erosion prevention, while SKAPS GC140 emphasizes filtration and water management. Choosing between them depends on the specific project requirements.

Selecting Geotextile Fabric in Filtration Operations

The selection of the correct geotextile for the application is critical to the long-term performance of the structure. Some factors to consider include desired flow rate, strength, pore size and type of aggregate being used.

One common question in selecting a geotextile pertains to the size of particle that will pass through. This is measured nominally in microns. For example, a 3.1 oz. nonwoven geotextile can contain particles as small as 297 microns, which is about one one-hundreth of an inch.

Sometimes filtering applications are measured in what's called U.S. Mesh. There are standard tables comparing U.S. Mesh to microns. In the case above, 297 microns equates to a 50 U.S. Mesh.

Where to Buy Geotextile Fabric

It's best to be supported by experts when deciding which type or types of geotextiles you'll need for your application. That's how Daniel B. Krieg can help.

Our company carries both woven and nonwoven fabric in several lengths and widths. Our polypropylene woven fabric is rot-proof, resistant to most chemicals and virtually unaffected by acids and alkaline. Our non-woven fabrics have a three-dimensional pore structure and are highly water-permeable, as is necessary in many geotextile end uses.

We also carry a variety of other erosion control products, such as silt fence, silt sacks, straw blankets, coconut blankets, turf reinforcement blankets and filter bags. Please call us at 717.792.0284 for assistance in deciding which product is best for you!

Improve Your Project Results With Geotextiles

Geotextiles have numerous and versatile uses in construction, paving and many other applications. They're important because they can:

- Improve drainage.

- Extend the life of pavement and other structures.

- Reduce maintenance costs.

- Prevent contamination of foundation soil.

- Provide a filter to help maintain clean water sources or prevent contamination.

You'll find geotextiles used in underground stabilization under railroad tracks, underground drainage providing a foundation for pipes and pillars, embankment protection, seawalls, bridge abutments, sports fields and numerous other situations.

Decades of research in geotextiles have shown increasing applications for these materials. The U.S. Federal Highway Administration (FHWA) reported that geosynthetic-reinforced soil can reduce bridge construction costs by 25 to 30 percent.

Now, geotextiles are beginning to benefit from the embedding of fiber optics. This process offers real-time situational awareness of the installation. With advanced monitoring, engineers can better anticipate when preventive or proactive maintenance may be required.

Contact Daniel B. Krieg Today

Whether you're constructing a roadway or parking lot, designing an erosion control plan or planning a drainage system, Daniel B. Krieg construction fabrics can provide a proven benefit to your project. Contact us today at 717.792.0284!

Product Ordering Information

Browse our full line of pavement maintenance products and learn how to place your order!

Contact Daniel B. Krieg For A Quote

Please contact Daniel B. Krieg, Inc. by filling out the form below, or by calling us at one of our locations.

Harrisburg Office

-

6730 Allentown Blvd.

6730 Allentown Blvd.

Harrisburg, PA 17112 Map It >> -

Mon - Thurs: 8:00 am - 4:00 pm

Fri : Closed

Sat : Closed

Sun : Closed

Mon - Thurs: 8:00 am - 4:00 pm

Fri : Closed

Sat : Closed

Sun : Closed -

800.334.4929

800.334.4929

717.564.2400

Fax: 717-558-2036 -

Contact Us

Contact Us

-

Leave a Review

Leave a Review

York Office

-

3331 Gulton Road

3331 Gulton Road

York, PA 17404 Map It >> -

Mon - Thurs: 7:00 am - 3:30 pm

Fri : 8:30 am - 3:30 pm

Sat : Closed

Sun: Closed

Mon - Thurs: 7:00 am - 3:30 pm

Fri : 8:30 am - 3:30 pm

Sat : Closed

Sun: Closed -

717.792.0284

717.792.0284

Fax: 717.792.0640 -

Contact Us

Contact Us

-

Leave a Review

Leave a Review

![]()

LEAVE US A REVIEW

Back To Top

Back To Top