Available in the following sizes and weights

Available in the following sizes and weights

- 3’x360′ 120 SY – 3.5 oz, 4.0 oz.

- 6’x300′ 200 SY – 3.5 oz.

- 12.5×360′ 500 SY – 3.5 oz., 4.0 oz., 4.5 oz., 6.0 oz., 8.0 oz., 12.0 oz. (Class 4A PennDot Approved)

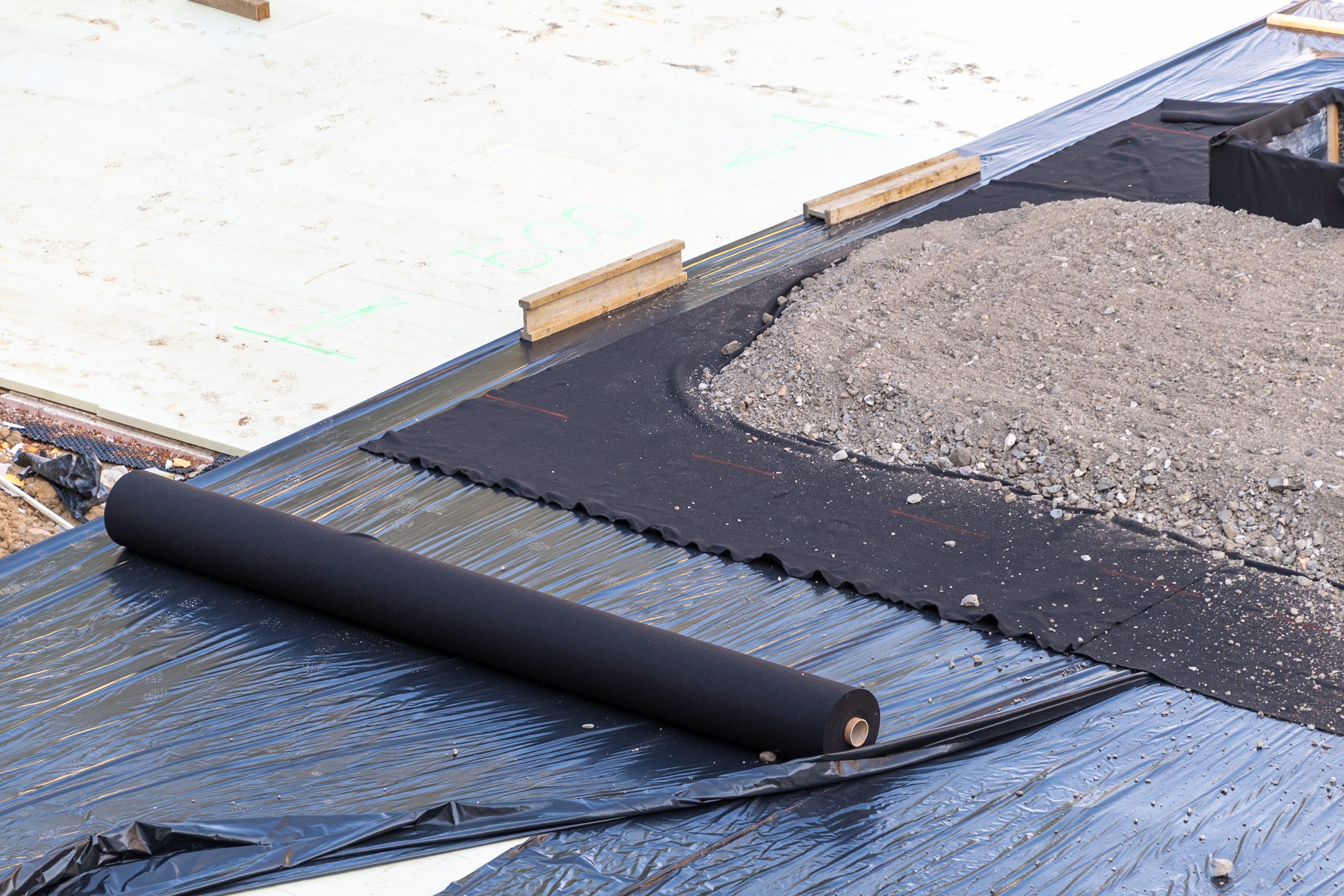

Geotextile fabrics are permeable materials used to promote soil stability as well as road and parking lot stabilization. Used across the U.S. by both federal and state organizations, these fabrics have become the norm for parking lot and highway construction.

Daniel B. Krieg offers a variety of both woven and nonwoven geotextile stabilization fabrics to improve the support structure and drainage of your public or private project.

Available in the following sizes and weights

Available in the following sizes and weights

Available in the following sizes and weights:

Availability:

Nonwoven geotextiles are multi-purpose fabrics used for filtration and separation. In its most common form, the fabric is made by mechanically combining fibers with barbed needles, known as needle punching. In this form, nonwoven geotextiles appear like black felt. Another popular method, known as spunbonding, involves spinning extruded filaments onto a collecting belt and bonding them through heat. In this form, you’ll usually see the nonwoven geotextiles colored gray.

On the other hand, woven geotextiles are constructed using polypropylene slit film yarns. They’re constructed from sheets of impermeable liner cut into strips, which are then woven together. Because of its high tensile strength, a woven geotextile is a cost-effective way to improve paved and unpaved surface separation and stability. You’ll commonly find woven geotextiles used in parking lots, building pads or construction site entrances. Because they’re less permeable than nonwoven fabrics, they’re not normally used for filtration.

Both the woven and nonwoven variations have their own unique advantages that make them ideal for different uses. Woven textiles may be the most commonly used, thanks to their low cost and high strength, but nonwoven textiles certainly find use in construction as well.

Both woven and nonwoven fabrics are used for a wide variety of purposes. Parking lots and highway construction are two of the most common uses of woven fabrics. Nonwoven fabrics are often used for asphalt overlay, drainage, pipe wrap and landscape fabric. Thanks to nonwoven fabric’s effective filtration benefits, it can also be used as pavement layer separation, railroad ballast separation, weed barrier and more.

A high tensile strength boosts stability exponentially.

Effectively prevents mixing between aggregate and soil.

Cuts down costs and saves production time.

Improves road performance and minimizes pavement rutting.